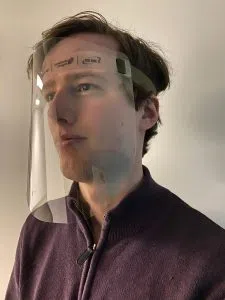

United Sign has re-tooled its signage production facility to fulfill an order of 10,000 medical face shields for the New Brunswick government, as well as 40,000 more in production to serve other jurisdictions.

Matt Symes, a founding partner and CEO of Moncton- and Halifax-based Symplicity Designs, had just bought United Sign in January. Making medical protective gear wasn’t part of the plan.

But with international supply chains weakened by the COVID-19 crisis, Symes and his team thought it necessary to have a local supply for essential protective gear.

In partnership with Symplicity Designs and with support from BMI, “we turned this around in two and a half weeks,” he said.

Symes didn’t realize at first that his company had the capabilities to make medical face shields. After fellow entrepreneur Greg Whynot suggested United Sign has the manufacturing capacity to do so, the company tried its hand, using its own “horrific prototype,” Symes said, admitting face shields weren’t the company’s strength.

But BMI President and CEO Martine Balcome suggested using an open-source design that was used to make shields used, among others, by frontline staff at Mount Sinai Hospital in New York City.

“So we got that over to the engineering team and within a day, we got the prototype mastered and good to go,” said Symes.

By cutting sheets of polycarbonate, the company said it can produce them quicker than shields made using 3D printers.

United Sign showed a sample to the New Brunswick government and received a contract to provide 10,000 shields soon after.

The company had gone from looking at “a great month” in early March to seeing all of its expected income delayed or cancelled within days.

“We got about two weeks of work left and nothing after that, when we were completely full before,” Symes said.

That forced the company to lay off 14 people and keep only four staff members. But with the switch to face shields, United Sign has been able to re-hire four people back.

The business pivot was led by Symplicity Designs’ organizational designer Jonathan Kummer, who sourced some of the 24 kilometres of elastic bands for the shields from craft shops and quilting stores around Nova Scotia.

Symes said while he sees United Sign play a role as a local manufacturer of protective medical gear for as long as needed, “it’s not a long-term business that we’ll be in.”

He said the pivot wasn’t a business decision, but a way to help the region’s frontline workers. It fit the company’s B Corp mission.

“It provides for a local alternative, it puts some people back to work in a purposeful way, it contributes to what Symplicity believes is a triple bottom line (outcome),” Symes said.

When supply lines go back to normal, it’s unlikely that North American manufacturers like United Sign will be able to compete with China on face shields, he said. In the long run, United Sign and its sister company Trim-Line are more focused on providing signage to help companies communicate the “new normal” and safety rules to customers and staff.

So far, United Sign has sold thousands of shields not only to the New Brunswick government but other essential workers who need it, like pharmacists, vets and in-home care workers.

With demand for face shields expected to remain high in the 16-to-24 months, the price for the raw materials have gone “through the roof” as supplies decreased, Symes said.

“We’ll run out of raw material at 60,000 [face shields] total,” he added. “But as long as we can do them and not lose money on them, we’ll continue to do them, if we can find the raw material.”

Learning from his own experience, Symes encourages other business owners to review their capabilities and see how they can provide a needed service or product.

“In times of crisis of this magnitude, businesses need to take a look inside and go, how can we be of service, how can we contribute?” he said.

He hopes it will inspire others “to stop looking at this virus in a way that paralyzes action, and turn around and go, how can we mobilize capability to be of service…because it’s going to take all of us.”

A version of this story was published in Huddle, an Acadia Broadcasting content partner.